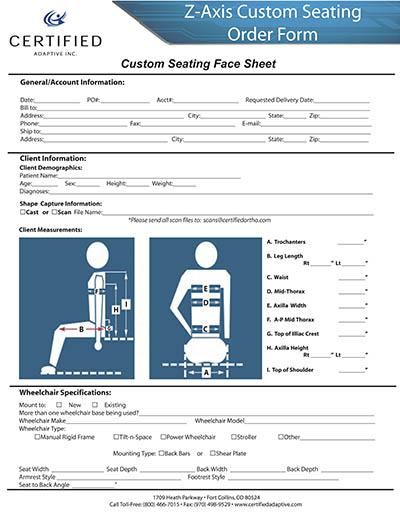

Turn Key Ordering Process

There is additional value in utilizing our turn key ordering process, which creates efficiencies and saves time and money. All of our custom seating systems utilize the Z-Axis Scanner to capture the shape of the mold into an electronic file. The scanner is extremely simple to use and requires minimal training that does not require a special seminar or workshop. Training can be accomplished over the phone. The software is included with the scanner, and we do not have any fees for training. We are offering the Z-Axis Scanner to any facility/ATP for only $500.00. This $500.00 will be credited after the fifth order making the scanner cost neutral.

This turn-key ordering process also saves the ATP an invaluable amount of time during evaluation and eliminates the need for a traditional plaster mold. (Please note that we will still accept plaster molds). In addition, whatever shape capturing system the facility/ATP is already utilizing will work with our scanning method, meaning there is no need to invest in a new molding frame or bags. After the shape capture is scanned, the file and order form is simply uploaded through our website or emailed saving shipping costs and time. Please see below for the step by step process.

Evaluation

Once custom seating option is deemed necessary, collaborate with your local ATP, Seating Specialist, PT/OT, and/or Certified Orthotist to determine exact seating needs and establish documentation. A team approach of professionals is recommended.

Mold & Shape Capture

Obtain simulation of optimal client posture utilizing molding bags. Certified’s system does not require a proprietary or specific molding bag system in order to accept scans or casts. Simply employ the molding system you currently have.

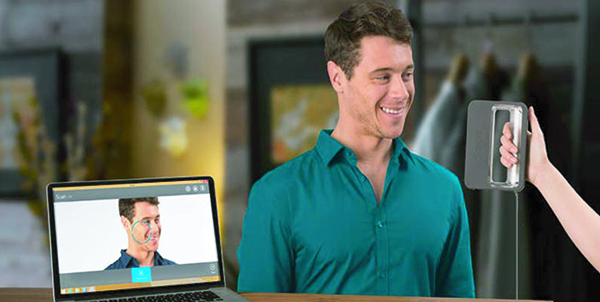

Scan

Certified’s portable scanner is the preeminent mobile scanning solution. With a single firewire connection, simply plug into laptop and you are ready to scan. Scanning is as easy as “point and click” without concern of overlaps or directional placement. Simply digitize your bean bag or plaster negatives, while obtaining the most accurate capture of the mold available on the market today. If you prefer traditional casting methods, simply send cast to Certified for fabrication. * Certified can also accept traditional plaster molds.

Product Selection

Select desired Custom Orthotic Seating System and options. Choices include full orthotic seating systems, custom backs, and custom cushions/seats, and the Z-Axis Custom Backs and Seats.

Placing Order

Complete order form containing all patient and product details/options and email scans to scans@certifiedortho.com or upload your scans directly HERE.

*If traditional cast is used, please mail to:

Certified Adaptive

1709 Heath Parkway

Fort Collins, CO 80524

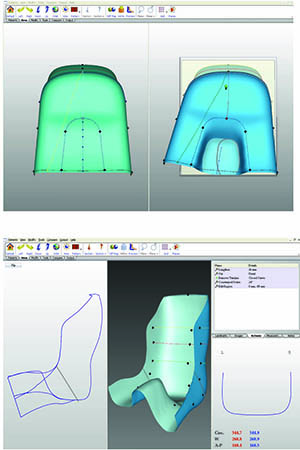

Order Received – Design Begins

Once Certified receives the mold or scan, design work begins in the seating software system. Certified’s seating software offers numerous options for creating fully customized modifications, build ups, and mold changes. Including seat to back angle, leg position, pommel additions, and/or any other desired changes. Once design work is complete, a final design model will be emailed to ATP for approval before the manufacturing process begins.

Manufacturing

After design work is complete, Certified will finalize the manufacturing of the custom seating system utilizing our state of the art Cad Carvers and skilled technicians. Completed seating systems can be shipped ready to mount or fully mounted if wheelchair is provided.